January 24, 2022

A lot of work goes into running a restaurant, but keeping your kitchen clean and in working order is especially crucial. A well-maintained grease interceptor, in particular, is key to a seamless operation. Grease interceptor backups can force you to halt business while also paying to clean up a nasty mess.

The following kitchen best management practices (BMPs) will help improve the longevity of your interceptor storage, reducing the cost to clean and maintain your interceptor, and keep your facility in good standing with local pretreatment authorities.

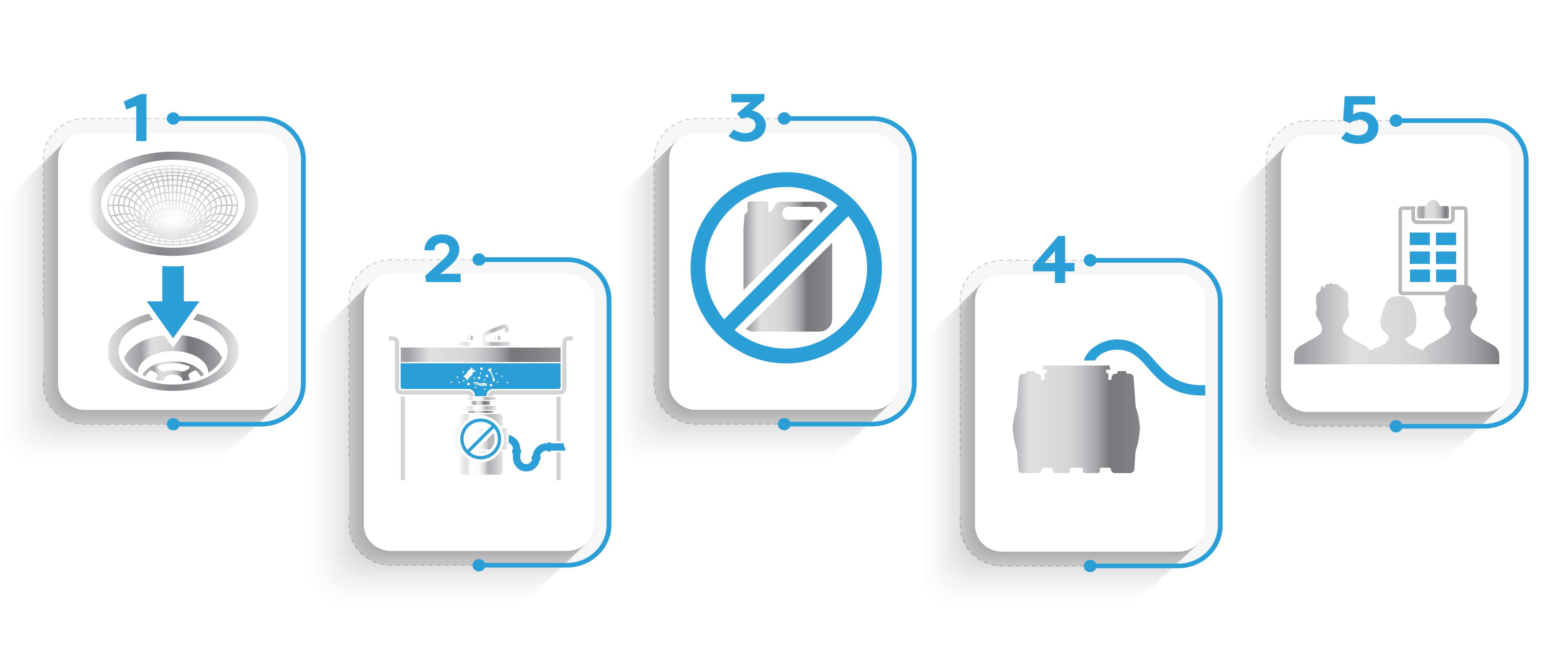

Keep solid waste out of your drain line. In many cases of interceptor backups, solids are to blame. Solids tend to result in immediate clogs, whereas grease problems happen over time. Try to resist the convenience of using food waste disposals and, instead, place any food waste in the trash. Debris screens in all floor and sink drains are a handy solution to keeping solid food waste out of your plumbing. Regularly and thoroughly empty these screens into the trash.

Dispose of grease and oil outside the drain line. This is something we've been taught since childhood. Dry wipe food waste from dishes to remove as much grease as possible before washing. Use disposable materials like paper towels to soak up excess grease and clean any spills. Never pour oil, fry oil, or melted lard or butter down the drain line. Dispose of these oils in a proper container (remember mom's jar of fat in the freezer?).

Never put chemicals for reducing grease into the drain system. The temporarily dissolved grease will bypass the interceptor and harden in downstream piping. Consider slow drainage as a sign you're due for maintenance.

Be cognizant of the pumpout process. Observe a pumper contractor at work to ensure the interceptor is fully pumped out and properly cleaned. Make sure the interceptor is refilled with clean cold water after pumpout. It's important to keep a maintenance log detailing pumpouts, repairs and the condition of the interceptor in case documentation is requested from an inspector.

Implement BMP training for kitchen staff. Enforce these practices as standard procedure and display them in an accessible area that offers staff a constant reminder.

For more information on using and maintaining your Schier Great Basin™ grease interceptor, reference your Great Basin™ Owners Manual.