June 23, 2022

Flow control devices restrict the rate of flow entering a grease interceptor to a maximum flow rate and, in some cases, serve as a vent for air intake to aid in separation performance. These devices may be installed either upstream of or within a grease interceptor.

Specific installation configurations may call for the use of flow control. For example, if a grease interceptor is installed a floor below the fixtures or has significant head pressure, high flow spikes can pressurize or even swamp an interceptor causing grease to bypass into the wastewater system. Flow control devices help prevent such occurrences.

Hydromechanical grease interceptors are tested and certified to a "type" of flow control (A, B, C, or D) set by the ASME/CSA standard. This ensures the unit functions properly and measures storage volume as well as efficiency.

NOTE: Schier was also the first to design hydromechanical grease interceptors certified to Type D, which allows for no flow control. This rating applies to Schier’s indoor/outdoor line of Great Basin™ grease interceptors. Learn more.

NOTE: Schier was also the first to design hydromechanical grease interceptors certified to Type D, which allows for no flow control. This rating applies to Schier’s indoor/outdoor line of Great Basin™ grease interceptors. Learn more.

Most commonly, flow control devices are installed upstream and outside of the interceptor (external flow control). These devices use a plate with a circular hole in it to limit the flow through the pipe with which it is installed. The area of the pipe determines the maximum flow. By blocking off a portion of that area, the flow rate cannot be any higher than the small opening is designed to allow.

Internal flow control devices offer a better solution because they are not contingent upon the plumber to install them, they are always present in the system if needed, and they are accessible for service or removal through the manhole cover of the interceptor. In addition, internal flow controls can be easily removed without disrupting the working kitchen.

External flow controls, on the other hand, will require that no water be running in order to service them, which involves unhooking the piping system from the fixture that the interceptor is supporting. Furthermore, they are often installed in hard-to-access areas and will add to the overall installation footprint, which can be an issue in smaller spaces.

External flow controls, on the other hand, will require that no water be running in order to service them, which involves unhooking the piping system from the fixture that the interceptor is supporting. Furthermore, they are often installed in hard-to-access areas and will add to the overall installation footprint, which can be an issue in smaller spaces.

What Does the Code Say?

What Does the Code Say?For decades, the Uniform Plumbing Code (UPC) mandated that flow control devices be installed in the tailpipe or drain outlet of each fixture connected to the interceptor. It also stated that these devices were to be installed outside of and not part of the grease interceptor, and no flow control device could have adjustable or removable parts.

Today, the Uniform Plumbing Code (section 1014.2 Hydromechanical Grease Interceptors) states the following:

“Plumbing fixtures or equipment connected to a Type A and B hydromechanical grease interceptor shall discharge through an approved type of vented flow control installed in a readily accessible and visible location. Flow control devices shall be designed and installed so that the total flow through such a device or devices shall at no time be greater than the rated flow of the connected grease interceptor. No flow control device having adjustable or removable parts shall be approved…”

“EXCEPTION: Listed grease interceptors with integral flow controls or restricting devices shall be installed in an accessible location in accordance with the manufacturer’s instructions.”

Schier’s flow control devices are the “exception” stated above.

In 2006, Schier was the first to develop patent-pending technology certified to Type C, which allows interceptors to ship with a built-in and removable flow control device.

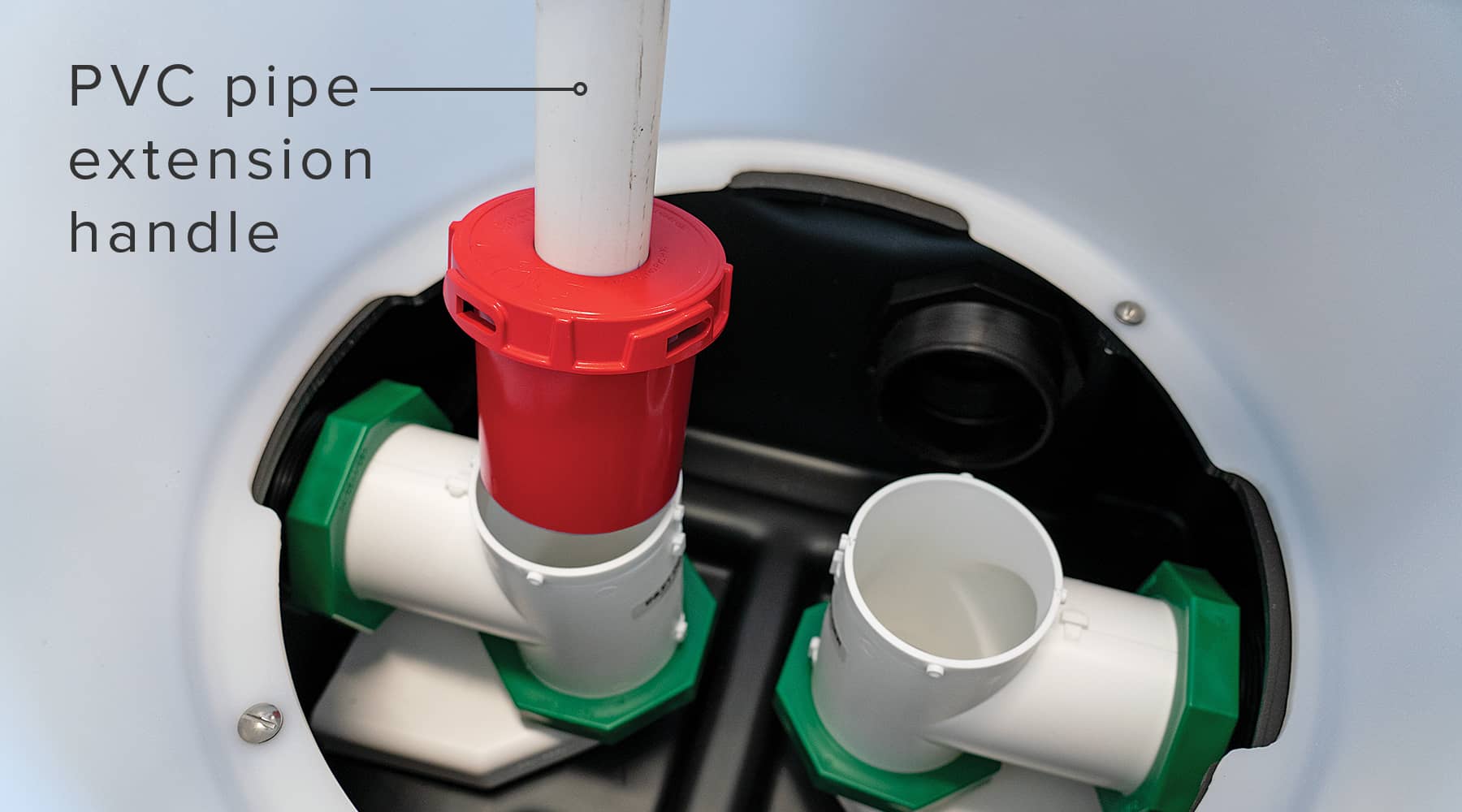

Instead of utilizing a standard circular orifice to restrict the flow like most manufacturers on the market today, Schier flow control devices are in the form of a cartridge in the inlet dip tube (diffuser) that blocks a portion of the cross-sectional area of the horizontal pipe entering the unit. This allows fluid to flow normally along the bottom of the pipe as it would under lower flows and only restricts it when the flow is high enough to hit the cartridge above. This limits the chance for clogs and allows solids to flow into the unit. The cartridge is also easily removable for service. You can even glue your own piece of 1 ½“ PVC pipe to the device to create an extension handle for removal from a deeply buried unit.

Instead of utilizing a standard circular orifice to restrict the flow like most manufacturers on the market today, Schier flow control devices are in the form of a cartridge in the inlet dip tube (diffuser) that blocks a portion of the cross-sectional area of the horizontal pipe entering the unit. This allows fluid to flow normally along the bottom of the pipe as it would under lower flows and only restricts it when the flow is high enough to hit the cartridge above. This limits the chance for clogs and allows solids to flow into the unit. The cartridge is also easily removable for service. You can even glue your own piece of 1 ½“ PVC pipe to the device to create an extension handle for removal from a deeply buried unit.

The built-in flow control feature applies to Schier’s indoor Great Basin™ grease interceptors GB1, GB2, and GB3, as well as indoor/outdoor grease interceptors GB-250 (@ 200 GPM) and GB-500 (all flow rates). To learn more about Schier’s grease interceptor products and accessories, or to discuss your jurisdiction requirements surrounding flow control, reach out to support@schierproducts.com.

The built-in flow control feature applies to Schier’s indoor Great Basin™ grease interceptors GB1, GB2, and GB3, as well as indoor/outdoor grease interceptors GB-250 (@ 200 GPM) and GB-500 (all flow rates). To learn more about Schier’s grease interceptor products and accessories, or to discuss your jurisdiction requirements surrounding flow control, reach out to support@schierproducts.com.