July 28, 2025

This article will explain what hydromechanical separation is and how hydromechanical grease interceptors (HGIs) work.

Plumbing and pretreatment professionals often ask, "What does hydromechanical mean?" and, more specifically, "How do hydromechanical grease interceptors differ from gravity grease interceptors?" These questions frequently arise when selecting or approving grease interceptors for commercial food service establishments (FSEs). While this article focuses on the first question, we address the second in a separate post, Debunking gravity grease interceptor myths.

The dictionary definition of hydromechanics is as follows: relating to a branch of mechanics that deals with the equilibrium and motion of fluids and of solid bodies immersed in them. The term hydromechanical grease interceptor was given its own definition in the 2006 edition of the Uniform Plumbing Code (UPC) when it was first introduced to the industry: a plumbing appurtenance or appliance that is installed in a sanitary drainage system to intercept non-petroleum fats, oil and grease (FOG) from a wastewater discharge and is identified by flow rate and separation retention efficiency. The design incorporates air entrainment, hydromechanical separation, interior baffling or barriers in combination or separately…” At the same time, the term grease trap was being retired as modern plumbing systems were moving towards uniform gas traps (P-Traps) to protect the interior of the building. As grease traps technically filled this role for many years, having a double trap in the system violated plumbing code. To this end, the term hydromechanical grease interceptor was created.

Unfortunately, no. It simply attempts to differentiate between passive grease interceptors that are tested and rated for performance and those that are not, such as gravity grease interceptors (GGI). All grease interceptors operate on the principle of gravity-differential separation (floating grease) even though they don’t all do the job in the same way. Distinguishing between various designs is incorporated into the standards that cover these devices, i.e. ASME A112.14.3 for hydromechanical interceptors or ANSI Z1001 for gravity interceptors.

All grease interceptors operate on the principle of gravity-differential separation (floating grease) even though they don’t all do the job in the same way. Distinguishing between various designs is incorporated into the standards that cover these devices, i.e. ASME A112.14.3 for hydromechanical interceptors or ANSI Z1001 for gravity interceptors.

Hydromechanical interceptors range in size from 10 liquid gallons to 1,500 liquid gallons; they are not necessarily small shoeboxes installed under the sink anymore. The design and performance of these units is scalable and quickly blurring the lines between interior and exterior interceptors of all types, HGI or GGI. The plumbing code allows for both, however pretreatment programs are moving towards performance based devices and eliminating gravity interceptors.

No. By definition, design incorporates not only hydromechanical separation, but also air entrainment and interior baffling or barriers in combination or separately… Let’s unpack each of these.

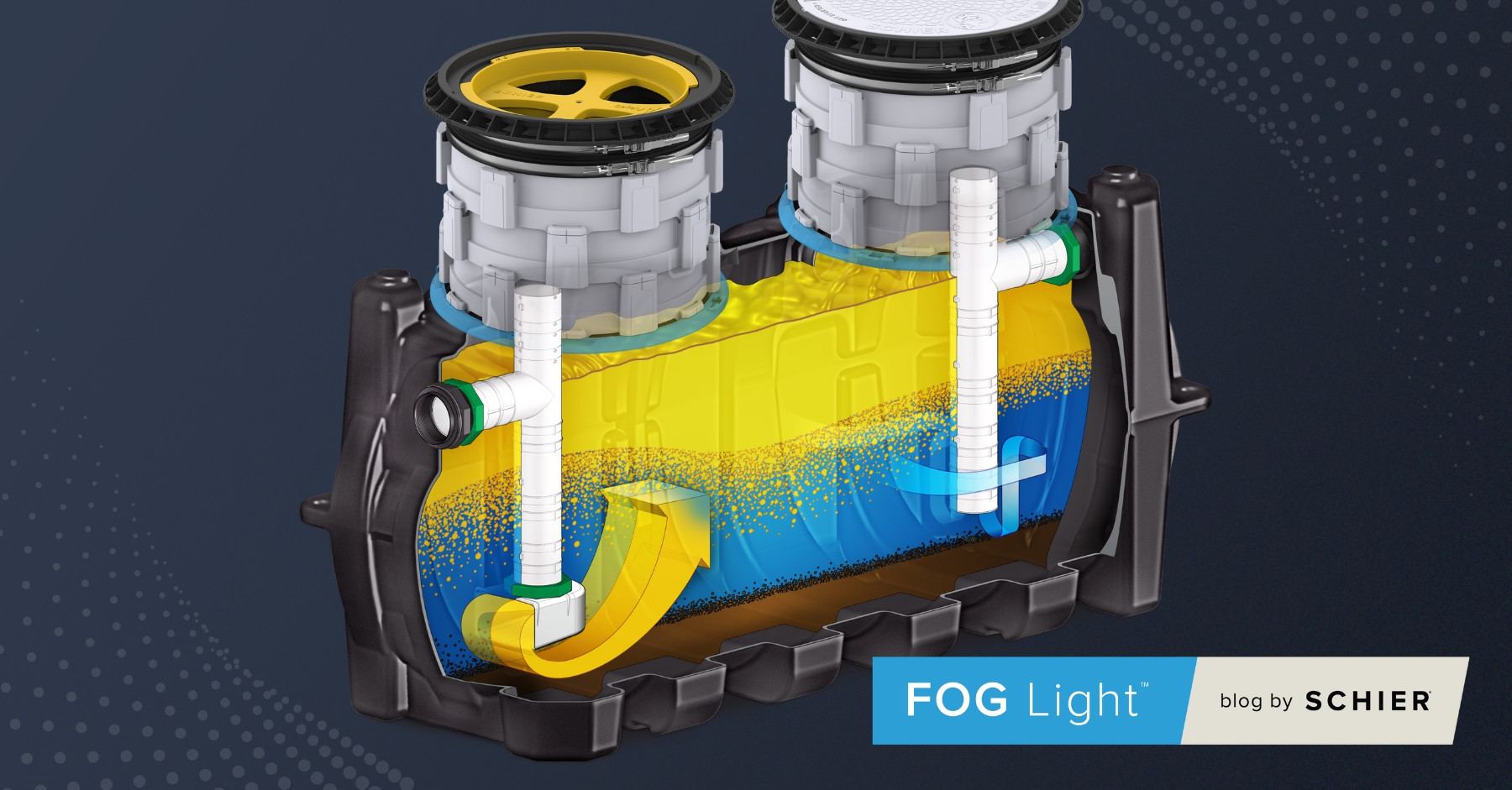

Air entrainment: Air entrainment is defined as: to draw along with or after oneself, or to draw in and transport by the flow of fluid. Water consists of two parts hydrogen and one part oxygen, which is to say that water cannot exist without air. In drainage systems, the flow of water from faucets, sometimes with aerators, draws more air along with the flow and incorporates venting. This ensures that the system flows properly. As it gets to the interceptor, proper design incorporates air entrainment to allow the grease to rise along with the air. Some interceptors also contain an orifice and air intake flow control to aid in separation and prevent bypass, this adds to air entrainment as well. All interceptors will have some element of air entrainment during operation. Baffles or barriers Baffles or barriers can act within some interceptors to help direct the flow of fluid in order to create good separation, Schier’s GB-1000 and GB-1500 for example. While these elements are included in some designs, they are not necessarily essential to the workings of all interceptors in the market. Tank geometry, inlet and outlet variations, and diffusion flow can take the place of baffles or barriers when third-party tested for performance. Baffles, if deployed correctly, can add additional grease capacity and efficiency to hydromechanical interceptors. They can also allow the unit to be certified as both a hydromechanical and gravity interceptors further blurring the line between GGIs and HGIs. Performance testing being the difference between the two.

Baffles or barriers Baffles or barriers can act within some interceptors to help direct the flow of fluid in order to create good separation, Schier’s GB-1000 and GB-1500 for example. While these elements are included in some designs, they are not necessarily essential to the workings of all interceptors in the market. Tank geometry, inlet and outlet variations, and diffusion flow can take the place of baffles or barriers when third-party tested for performance. Baffles, if deployed correctly, can add additional grease capacity and efficiency to hydromechanical interceptors. They can also allow the unit to be certified as both a hydromechanical and gravity interceptors further blurring the line between GGIs and HGIs. Performance testing being the difference between the two.

In summary, the terms hydromechanical and gravity do not describe what is really different about the systems. Hydromechanical interceptors incorporate components to achieve better performance and are tested to ensure this fact. Moving parts or filters are not part of the design which would make them more complicated. Gravity differential separation is how grease is separated from the waste stream. While components may include diffusers (shape, height, variations between the inlet and outlet), baffles, air entrainment, tank geometry, and overall volume, each interceptor must be certified individually to failure to discover the maximum grease capacity. Grease capacity is essential to provide protection of the conveyance system and we now see solutions ranging from 70 pounds of grease capacity all the way to 10,061 pounds of grease capacity for use in both interior and exterior applications.

Testing grease interceptors to hydromechanical performance enables right sizing via grease production sizing method (GPSM). Learn more about performance testing, right sizing, and the #1 grease interceptor sizing application Grease Monkey® on our FOG Light page.