October 2, 2025

When you hear the term ‘retention time,’ it is usually associated with gravity grease interceptor (GGI) systems and wastewater treatment plants. While both deal with water treatment, the way they use retention time is entirely different. Let’s unpack both.

If you’ve studied the differences between GGIs and hydromechanical grease interceptors (HGIs), you know that HGIs are engineered and performance-rated. Their performance is measured by the flow rate of the fixtures they serve and their grease capacity at a designated efficiency which must exceed 90%. If you’d like more information on the differences between GGIs and HGIs, check out another one of Schier’s blog posts.

Unlike HGIs, GGIs are not performance rated. They operate much like septic tanks, relying on two primary elements:

A large body of water

Retention time

Because GGIs are not performance rated, industry “rules of thumb” evolved. One common standard is the 25% Rule, which requires that GGIs be pumped when they are 25% full of grease and solids. Another is the assumption that GGIs should be sized for a 30-minute retention time. But where did that 30-minute rule come from? And is there any technical justification for it?

It turns out, the idea originated from the textbook Small and Decentralized Wastewater Management Systems (1998) by George Tchobanoglous and Ronald Crites. The authors suggested that a septic tank used as a grease interceptor should detain liquid for at least 30 minutes to allow grease separation. However, this statement was not backed by research, studies, or real-world testing — just the assertion that 30 minutes “should be adequate.” An example of this would be taking an average flow rate of 50 gallons per minute times 30 minutes. This would equal a 1,500 liquid gallon gravity interceptor.

So how well does this work in practice?

Commercial GGIs are just residential septic tanks repurposed for grease capture. Septic tanks work because they’re designed with very long retention times (often 24 hours) and low flow rates. Once GGIs were applied in commercial kitchens, sizing practices evolved.

From 1982 to 2003, the Uniform Plumbing Code (UPC) included Appendix H, which sized GGIs based on meals per peak hour, flow rate, retention time and storage factor. This often led to oversized interceptors. Typically, sizing led to interceptor volumes between 5,000 and 10,000 gallons in full service restaurants.

In 2006, Appendix H was removed. The UPC (and the IPC) switched to sizing GGIs using drainage fixture units (DFUs), with tables assigning interceptor volumes to DFU loads — intended to provide at least 30 minutes of retention. Sizing using DFU loads lead to a gravity interceptor between 1,000 gallons (35 DFUs) and 3,000 gallons (342 DFUs).

However, both methods proved problematic. Oversized interceptors often generated lethal amounts of hydrogen sulfide (H₂S) gas and discharged elevated BOD/TSS. Undersized units, meanwhile, frequently short-circuited, reducing separation efficiency during peak flows.

The Water Environment Research Foundation (WERF) studied these issues in 2008. Their report, Assessment of Grease Interceptor Performance, found that GGIs were generally improperly sized and often failed due to short-circuiting.

This raises important questions:

How does a fixed 30-minute retention time account for widely varying flow rates?

What happens when hot water surges alter flow velocity and patterns?

At what point does accumulated grease and solids reduce separation efficiency?

Without proper testing, how can we assume 30 minutes is adequate for grease separation in every GGI?

In contrast, wastewater treatment plants (WWTPs) use retention time — often called hydraulic retention time (HRT) — as a carefully calculated design and operational parameter. HRT determines how long wastewater remains in tanks or basins, giving biological, chemical and physical processes time to work.

If water moves too quickly, solids don’t settle, organic matter isn’t degraded, and pathogens aren’t reduced — leading to poor effluent quality. In processes like activated sludge and anaerobic digestion, retention time directly affects microbial activity and treatment efficiency. Engineers design HRT based on flow rates, volume, and treatment goals to balance effectiveness with capacity.

Properly calculated retention time in WWTPs provides stability, consistency, and regulatory compliance. It buffers against flow fluctuations and ensures effluent quality is maintained.

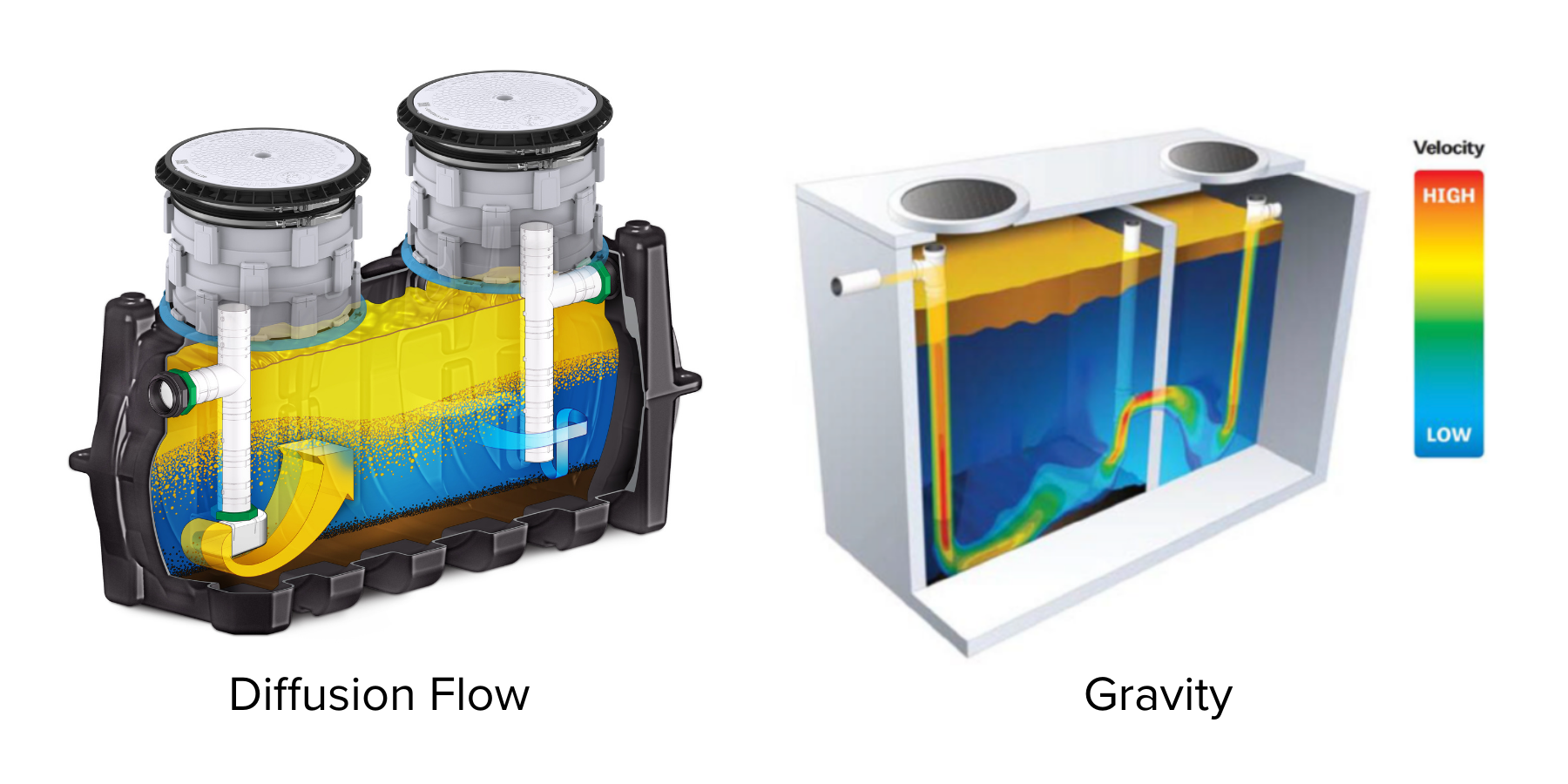

Properly designed hydromechanical interceptors don’t depend on long retention times. Grease naturally wants to float; it separates quickly when designed flow patterns allow it. The captured grease is then removed by pumping contractors and transported to treatment plants — where retention time does matter.

Consider this example:

A hydromechanical interceptor rated at 200 GPM holds 277 gallons of water.

During testing, 480 gallons of water plus 40 lbs of molten lard are run through it in just 110 seconds (200 GPM).

Despite this extreme surge, the unit achieved 93.5% efficiency, certified for more than 1,196 lbs of grease capacity.

The calculated retention time in this scenario was only 83 seconds — far less than 30 minutes, yet still highly effective.

Translation: That’s like blasting a fire hose of 150°F grease-laden water at the unit — and it still captured grease at over 90% efficiency.

See our state of the art test lab in action

The industry has relied on a 30-minute retention time rule for GGIs without real-world validation. Meanwhile, wastewater treatment plants demonstrate the importance of scientifically justified retention time.

HGIs, on the other hand, show that performance testing beats assumptions. With engineered design and validated efficiency, they deliver reliable grease capture — even under extreme conditions.