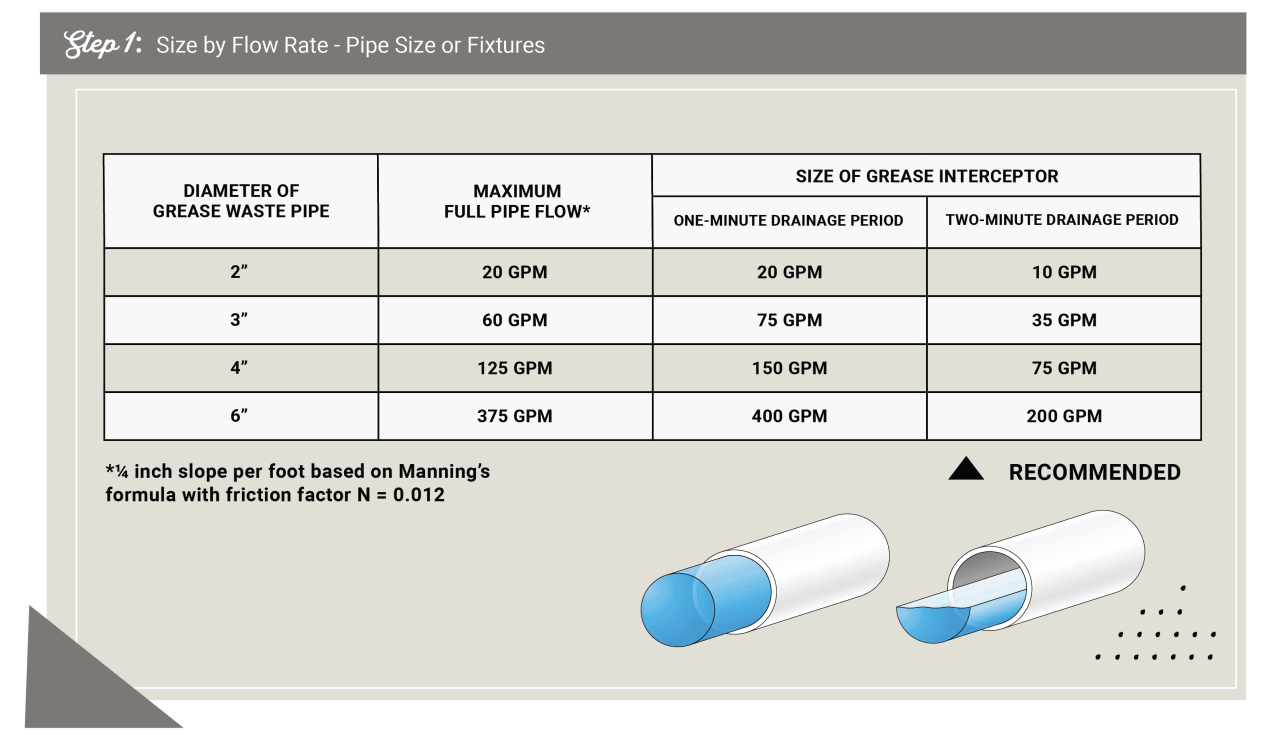

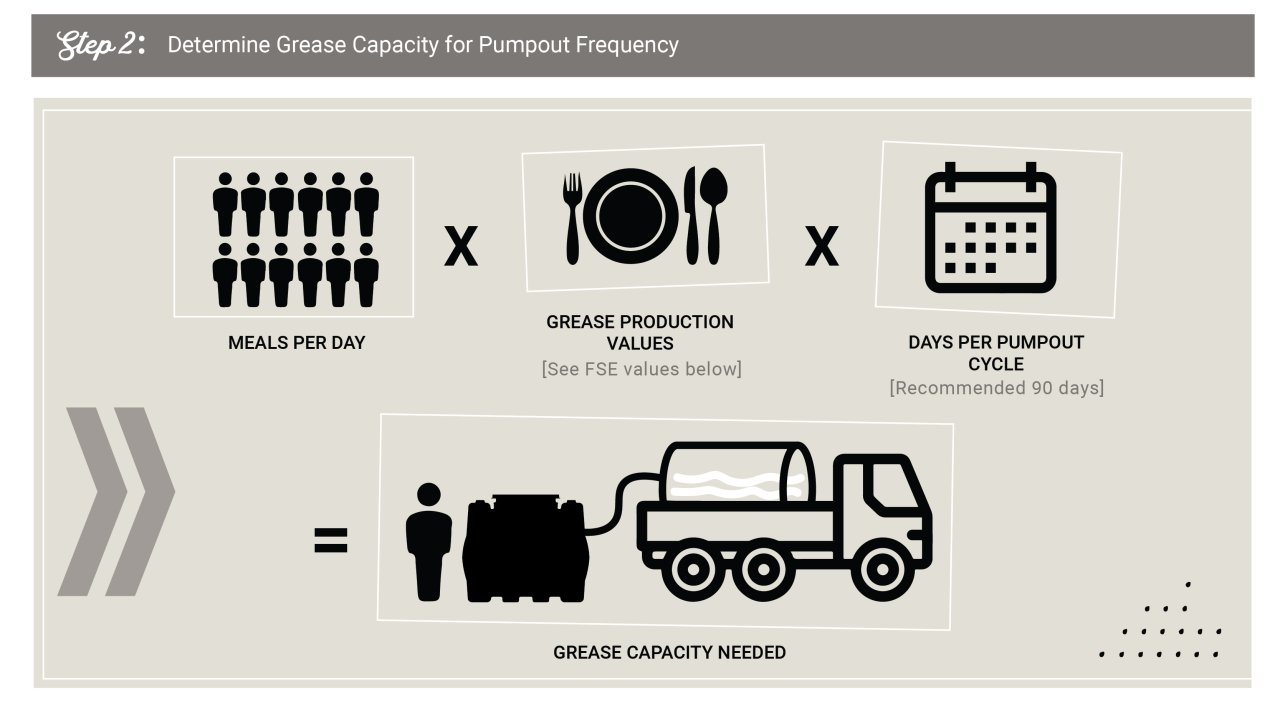

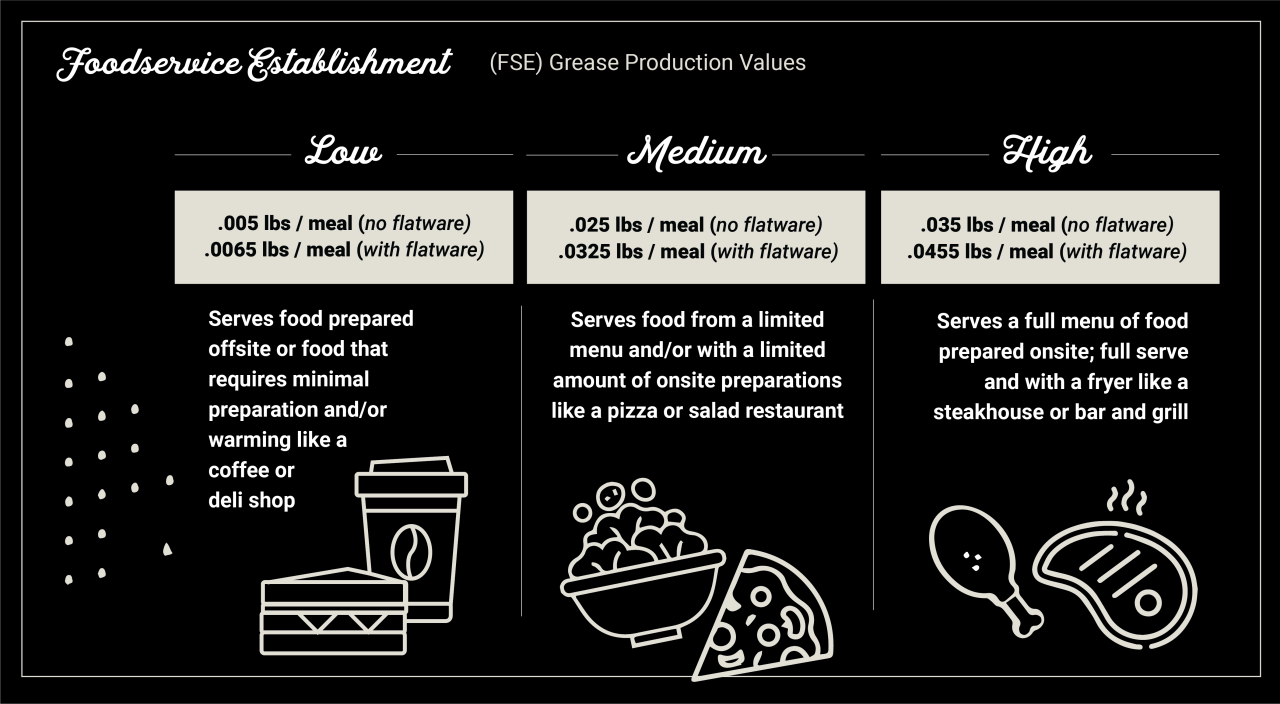

Many plumbing codes focus on either flow rate or liquid volume to size a grease interceptor, which can lead to undersizing or oversizing. Schier considers both flow rate and grease production to determine the capacity of the interceptor and its recommended pumpout frequency.

A correctly sized grease interceptor reduces maintenance costs for restaurants as well as the chance of a messy and costly clog/backup. Right sizing is critical in choosing the correct grease interceptor, and we’ve got it down to a science. It’s called Grease Production Sizing Method (GPSM).