December 29, 2021

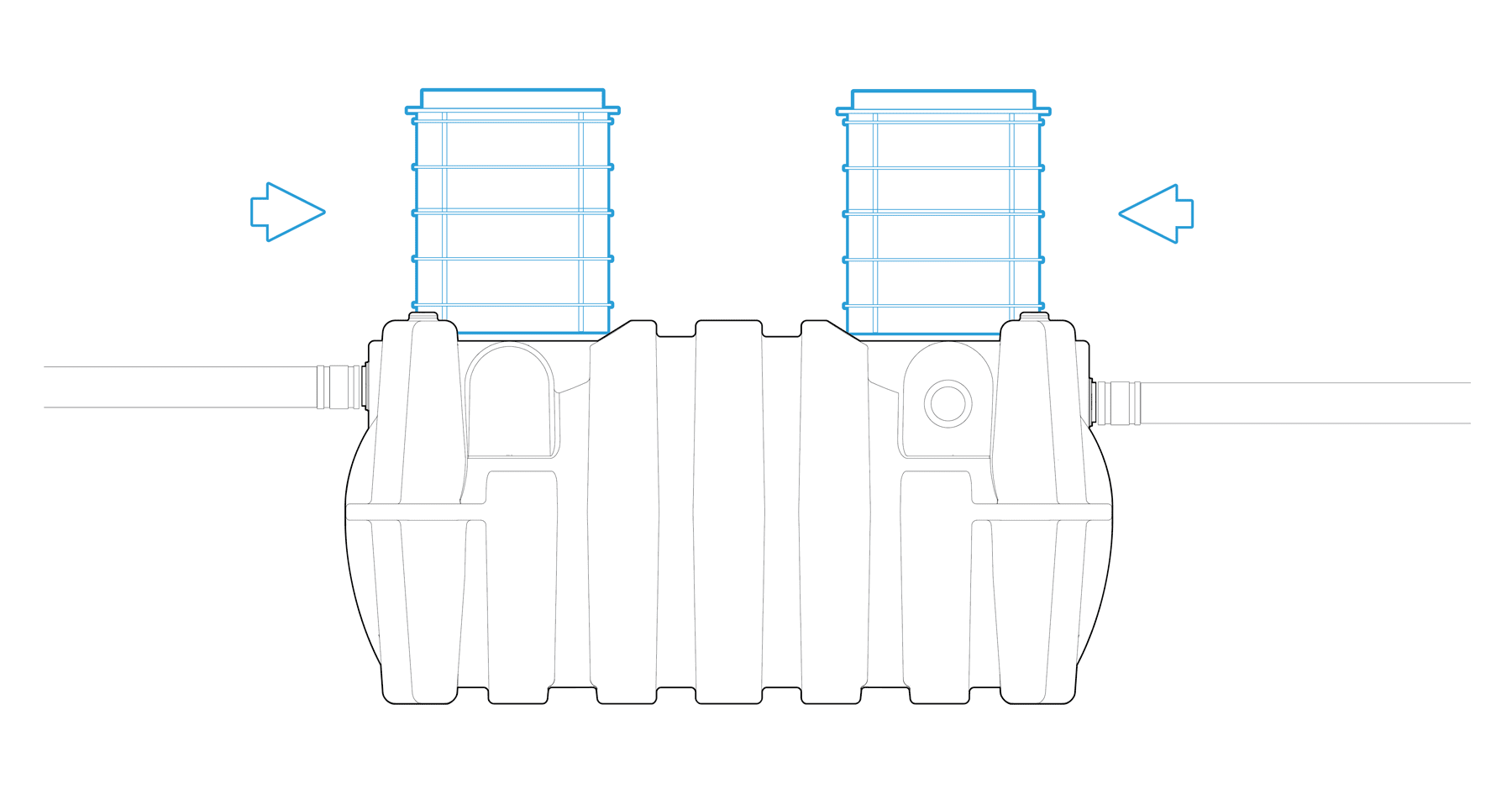

Below-grade grease interceptor installation offers flexibility for food service establishments (FSEs) with space constraints, especially where larger units are required. However, because burial depths can vary, the need for adjustability will usually arise with such installations. Thus, Schier created the Field Cut Riser (FCR) System for all base units.

This system allows for easy on-site adjustability to meet finished grade requirements by simply trimming unneeded height off the riser bodies. Schier's Field Cut Risers (FCR1 and FCR2) are made of light-weight polyethylene plastic and can be easily cut using a Sawzall. The ease and flexibility of this accessory eliminates job site delays while waiting for custom-built risers, ensuring projects finish on time and on budget.

IMPORTANT PRODUCT NOTES:

IMPORTANT PRODUCT NOTES:A maximum of two FCR1 risers and a maximum of three FCR2 risers can be stacked on top of one another at heights of 25" and 94" (respectively). The topmost riser may be cut based on your determined riser height.

The unassembled FRC2 includes two riser halves to be connected by applying silicone sealant to the edge of each half, then immediately assembling the riser halves and fastening the supplied screws.

Reference the FCR1 Specification & Installation Guide and the FCR2 Specification & Installation Guide for complete product details and installation instructions.

![]()