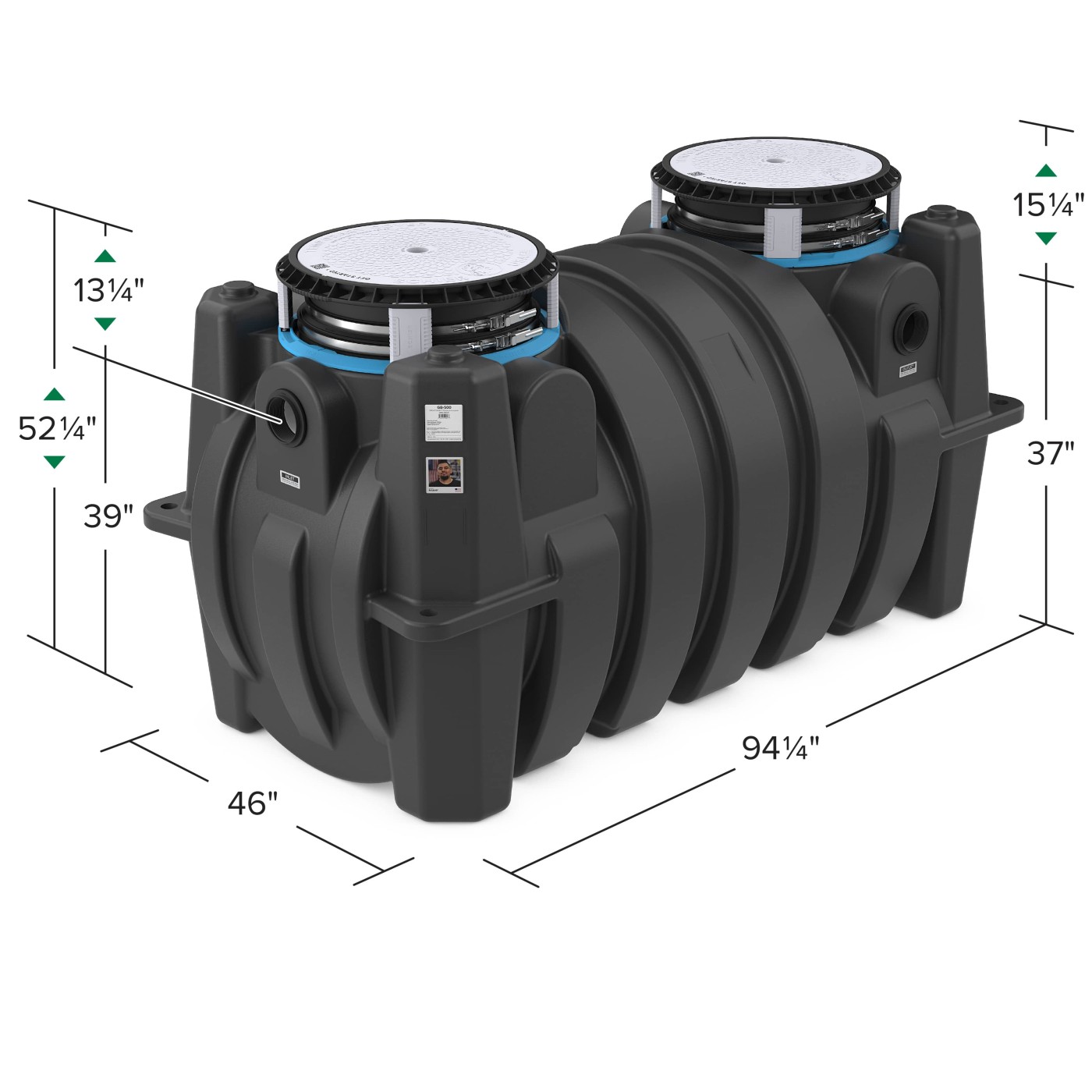

100/200 GPM grease interceptor

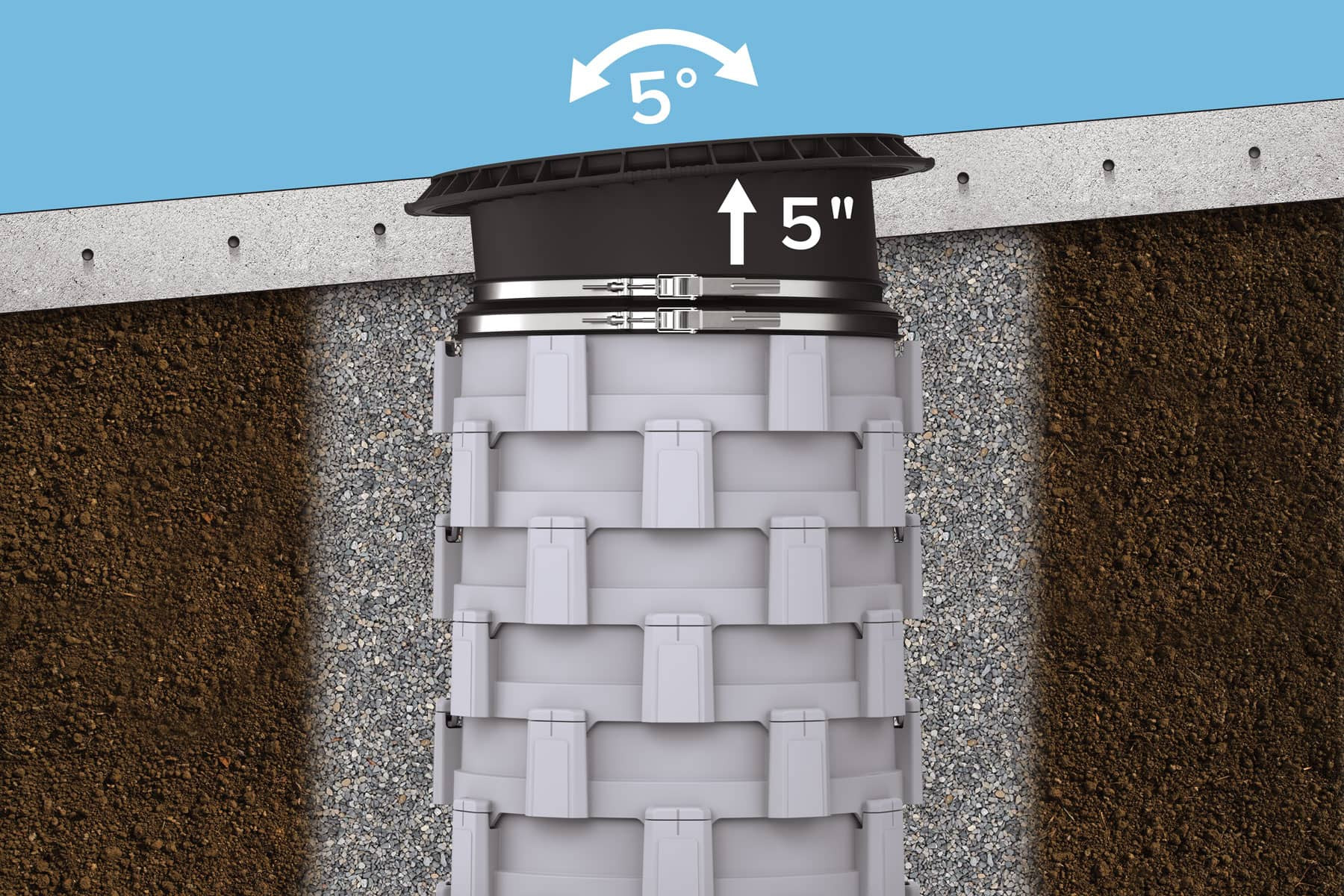

The lifetime guaranteed GB-500 offers best-in-class certified grease capacity and 25% kitchen solids waste capacity. It is rotationally molded from high density polyethylene with deep structural contours to handle any installation scenario: above grade, buried, indoor or outdoor. Use the Fast Pitch (see FP24) riser system to bring covers to finish grade with speed and precision. The triple outlet feature allows for installation flexibility, including the ability to connect an unused outlet for remote pumpout (see PP3).

NEW: Recertified to Type D: No Flow Control Required. Learn more about Type D.

More features:

Hydromechanical performance, third-party certified

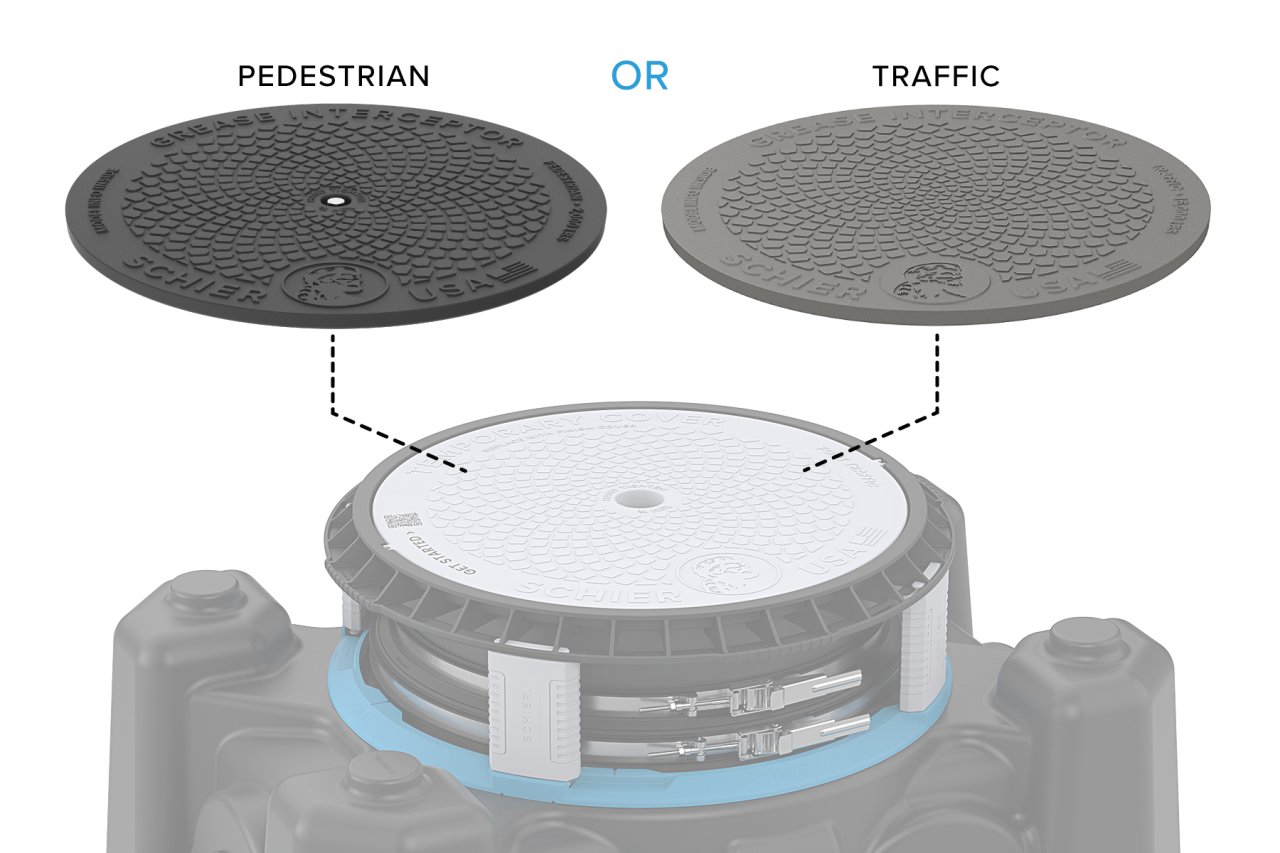

Safety Star® access restrictor prevents accidental entry

Sold with temporary cover to be replaced post-install with finish cover